smart board secondary display

smart board secondary display.In the production process of mobile phone screens, the protective glass, touch screen, and display screen need to be laminated twice. If the frame paste display is used, the display effect will be greatly reduced, and if the full paste yield is used, it will be a problem. Due to the laminating production process between the protective glass, touch screen, and display screen, the yield is greatly reduced. If the number of laminations can be reduced, the yield of full lamination will undoubtedly be improved. At present, several development directions have emerged: OGS solutions dominated by original touch screen manufacturers , and On Cell and In Cell technology solutions dominated by panel manufacturers. At present, more powerful display panel manufacturers tend to promote On-Cell or In-Cell solutions. The main reason is that they have display production capabilities, that is, they tend to make the touch layer on the display; and touch module manufacturers or upstream materials Manufacturers tend to OGS, that is, the touch layer is made on protective glass, the main reason is to have strong manufacturing process capabilities and technology. The common points of the two can reduce the number of laminations, which can save costs and improve the yield of lamination. In addition, due to the lack of a touch layer, it can also achieve the purpose of saving material costs and achieving thinness. Among them, Apple iPhone5 uses In-Cell technology.

IQTouch K Interactive Display

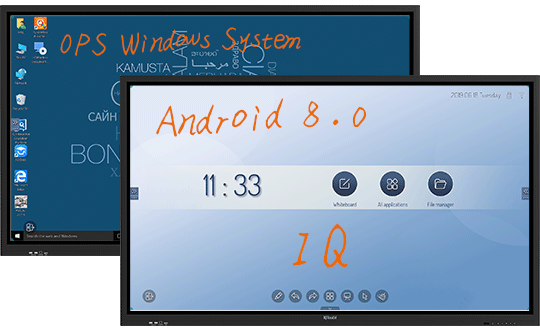

smart board secondary display.In the production process of mobile phone screens, the protective glass, touch screen, and display screen need to be laminated twice. If the frame paste display is used, the display effect will be greatly reduced, and if the full paste yield is used, it will be a problem. Due to the laminating production process between the protective glass, touch screen, and display screen, the yield is greatly reduced. If the number of laminations can be reduced, the yield of full lamination will undoubtedly be improved. At present, several development directions have emerged: OGS solutions dominated by original touch screen manufacturers , and On Cell and In Cell technology solutions dominated by panel manufacturers. At present, more powerful display panel manufacturers tend to promote On-Cell or In-Cell solutions. The main reason is that they have display production capabilities, that is, they tend to make the touch layer on the display; and touch module manufacturers or upstream materials Manufacturers tend to OGS, that is, the touch layer is made on protective glass, the main reason is to have strong manufacturing process capabilities and technology. The common points of the two can reduce the number of laminations, which can save costs and improve the yield of lamination. In addition, due to the lack of a touch layer, it can also achieve the purpose of saving material costs and achieving thinness. Among them, Apple iPhone5 uses In-Cell technology. IQTouch K interactive touch screen feature 20-point touch and dual system -- Android 8.0 system and optional OPS Windows 10Pro system. Its 4K UHD resolution facilitates presentations and collaboration. With optional multi-screen casting software, IQClass 6.0 and installation-free IQClass Plus software, IQTouch K Series can help create an interactive and collaborative teaching atmosphere in class.

Let’s See IQTouch K Interactive Display

4K UHD Display

Stunning 4K UHD can display a cystal clear image on

screen.

20 Touch Points

Enable an interactive and collaborative teaching atmosphere

in classroom.

Built in Wifi hotspot & Optional

Multi-screen casting Software

Support to cast your devices to the screen wirelessly,

and your devices can control the screen wirelessly.

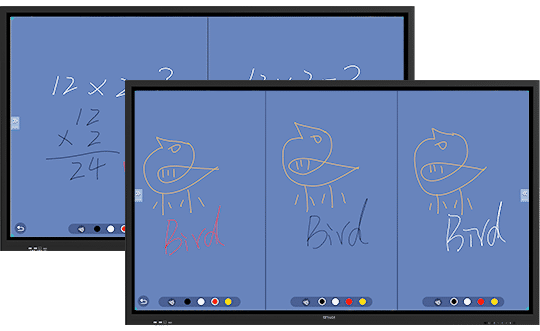

Easy-to-Use Built-in Whiteboard

Software

Built-in Whiteboard software under Android system allow to do

two separate screen teaching and three separate screen teaching.

All-channel Annotation

Enable to annotate under Android system and

Windows system.

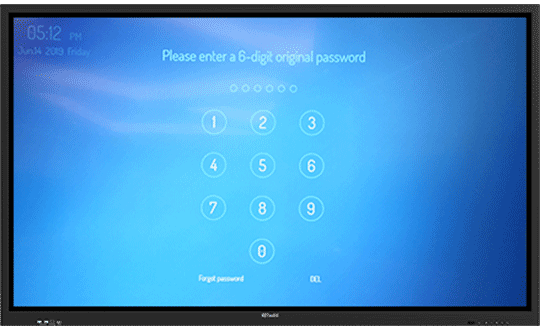

Power On/Off Lock and Screen Lock can

be Set with A Password Respectively

Support to lock screen and lock power on/off button

to avoid student

malfunction and secure privacy.

To compare with our other IQTouch Series

RESOURCE FOR YOU

Resource for you

Product Tag

Send us a message

Get in touch

-

![icon-phone]() +86-591-38202660

+86-591-38202660

-

![icon-mob]() +86-15280405902

+86-15280405902

-

![icon-mail]() iqboard@iqboard.net

iqboard@iqboard.net

-

![icon-addr]() 6th Bldg. High-Tech Base.

6th Bldg. High-Tech Base.

Fuzhou FuJian Prov. China

Solutions

Copyright © 2017.Returnstar Interactive Technology Group Co., Ltd All rights reserved.