touch screen display car

touch screen display car.When a finger touches the screen, the two conductive layers that are normally insulated from each other make a contact at the touch point. Because one of the conductive layers is connected to a 5V uniform voltage field in the Y axis direction, the voltage of the detection layer changes from zero to Non-zero, after this on-state is detected by the controller, A / D conversion is performed, and the Y-axis coordinate of the touch point can be obtained by comparing the obtained voltage value with 5V, and the X-axis coordinate can be obtained in the same way This is the most basic principle common to all resistive technology touch screens. The key to resistive touch screens is materials technology. The resistive screen is divided into four-wire, five-wire, six-wire and other multi-line resistive touch screens according to the number of outgoing lines. The resistive touch screen is coated with two layers of OTI transparent oxide metal conductive layers on the surface of strengthened glass. The outermost layer of OTI is used as a conductive body. 0V voltage field, the two layers of OTI are separated by small transparent isolation points. When a finger touches the screen, a contact point appears between the two OTI conductive layers. The computer detects the voltage and current at the same time, calculates the position of the touch, and the response speed is 10-20ms.

IQTouch K Interactive Display

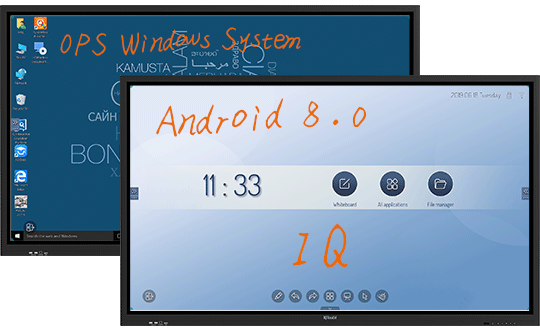

touch screen display car.When a finger touches the screen, the two conductive layers that are normally insulated from each other make a contact at the touch point. Because one of the conductive layers is connected to a 5V uniform voltage field in the Y axis direction, the voltage of the detection layer changes from zero to Non-zero, after this on-state is detected by the controller, A / D conversion is performed, and the Y-axis coordinate of the touch point can be obtained by comparing the obtained voltage value with 5V, and the X-axis coordinate can be obtained in the same way This is the most basic principle common to all resistive technology touch screens. The key to resistive touch screens is materials technology. The resistive screen is divided into four-wire, five-wire, six-wire and other multi-line resistive touch screens according to the number of outgoing lines. The resistive touch screen is coated with two layers of OTI transparent oxide metal conductive layers on the surface of strengthened glass. The outermost layer of OTI is used as a conductive body. 0V voltage field, the two layers of OTI are separated by small transparent isolation points. When a finger touches the screen, a contact point appears between the two OTI conductive layers. The computer detects the voltage and current at the same time, calculates the position of the touch, and the response speed is 10-20ms. IQTouch K interactive touch screen feature 20-point touch and dual system -- Android 8.0 system and optional OPS Windows 10Pro system. Its 4K UHD resolution facilitates presentations and collaboration. With optional multi-screen casting software, IQClass 6.0 and installation-free IQClass Plus software, IQTouch K Series can help create an interactive and collaborative teaching atmosphere in class.

Let’s See IQTouch K Interactive Display

4K UHD Display

Stunning 4K UHD can display a cystal clear image on

screen.

20 Touch Points

Enable an interactive and collaborative teaching atmosphere

in classroom.

Built in Wifi hotspot & Optional

Multi-screen casting Software

Support to cast your devices to the screen wirelessly,

and your devices can control the screen wirelessly.

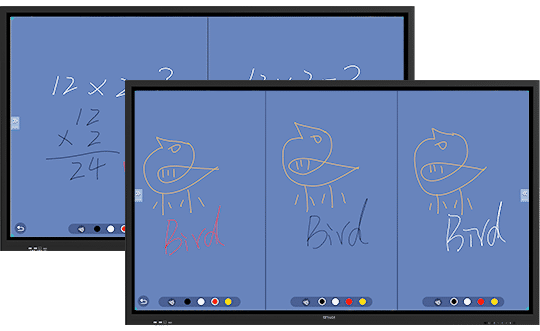

Easy-to-Use Built-in Whiteboard

Software

Built-in Whiteboard software under Android system allow to do

two separate screen teaching and three separate screen teaching.

All-channel Annotation

Enable to annotate under Android system and

Windows system.

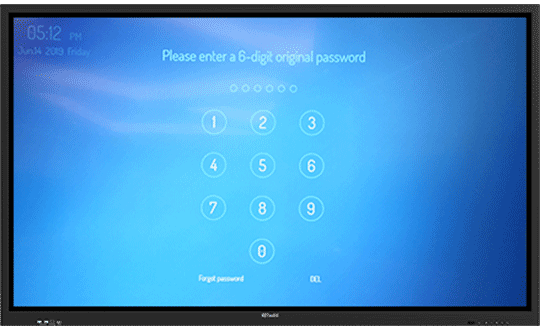

Power On/Off Lock and Screen Lock can

be Set with A Password Respectively

Support to lock screen and lock power on/off button

to avoid student

malfunction and secure privacy.

To compare with our other IQTouch Series

RESOURCE FOR YOU

Resource for you

Product Tag

Send us a message

Get in touch

-

![icon-phone]() +86-591-38202660

+86-591-38202660

-

![icon-mob]() +86-15280405902

+86-15280405902

-

![icon-mail]() iqboard@iqboard.net

iqboard@iqboard.net

-

![icon-addr]() 6th Bldg. High-Tech Base.

6th Bldg. High-Tech Base.

Fuzhou FuJian Prov. China

Solutions

Copyright © 2017.Returnstar Interactive Technology Group Co., Ltd All rights reserved.