smart board 2075 pro display

smart board 2075 pro display.In the second half of the 1990s, the second generation of portable information terminals added functions such as communication. Even in the third generation, they were still used as an auxiliary tool to help users remember, browse information or perform services in daily life. Parallel to this is the year-to-year advancement of liquid crystal displays, so the requirements for the optical characteristics or durability of touch screens will become more stringent year by year. The key to the resistive touch screen is material technology. Commonly used transparent conductive coating materials are: A, ITO coating, indium oxide, weak conductor, the characteristic is when the thickness is reduced to 1800 Angstroms (Angstrom = 10-10 meters) It will suddenly become transparent at the following time, the light transmittance will be 80%, and then the light transmittance will decrease when it is thinner, and it will rise to 80% when the thickness is 300 angstroms. ITO is the main material used in all resistive touch screens and capacitive touch screens. The working surface of these two technology touch screens is ITO coating. ?? B. Nickel-gold coating, the outer conductive layer of the five-wire resistive touch screen uses a highly ductile nickel-gold coating material. Because the outer conductive layer is frequently touched, the use of a ductile nickel-gold material is intended to extend Service life, but the process cost is relatively high. According to the different coatings and the number of wires, the resistive touch screen is divided into four-wire resistive screen and five-wire resistive screen. Their common points are: ?? A, high resolution, high-speed transmission response; ?? B, one-time calibration, high stability; ?? C, high surface hardness, reduce scratches, scratches and chemical treatment; ?? D. Two kinds of surface treatments can be performed (that is, glossy and matte). The differences are as follows: ?? The two transparent metal layers of the four-wire resistive touch screen each increase 5V constant voltage when working: one vertical direction and one horizontal direction. A total of four leads are required for the entire touch screen. Its service life is no less than 1 million times for a single touch, and no less than 100,000 times for a line.

IQTouch K Interactive Display

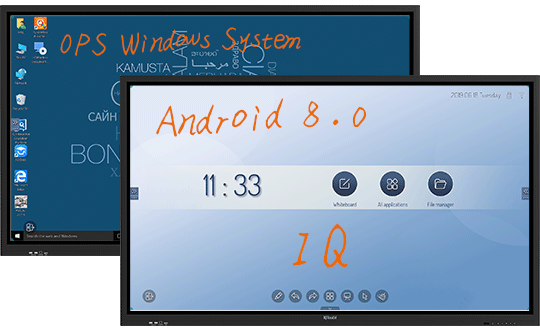

smart board 2075 pro display.In the second half of the 1990s, the second generation of portable information terminals added functions such as communication. Even in the third generation, they were still used as an auxiliary tool to help users remember, browse information or perform services in daily life. Parallel to this is the year-to-year advancement of liquid crystal displays, so the requirements for the optical characteristics or durability of touch screens will become more stringent year by year. The key to the resistive touch screen is material technology. Commonly used transparent conductive coating materials are: A, ITO coating, indium oxide, weak conductor, the characteristic is when the thickness is reduced to 1800 Angstroms (Angstrom = 10-10 meters) It will suddenly become transparent at the following time, the light transmittance will be 80%, and then the light transmittance will decrease when it is thinner, and it will rise to 80% when the thickness is 300 angstroms. ITO is the main material used in all resistive touch screens and capacitive touch screens. The working surface of these two technology touch screens is ITO coating. ?? B. Nickel-gold coating, the outer conductive layer of the five-wire resistive touch screen uses a highly ductile nickel-gold coating material. Because the outer conductive layer is frequently touched, the use of a ductile nickel-gold material is intended to extend Service life, but the process cost is relatively high. According to the different coatings and the number of wires, the resistive touch screen is divided into four-wire resistive screen and five-wire resistive screen. Their common points are: ?? A, high resolution, high-speed transmission response; ?? B, one-time calibration, high stability; ?? C, high surface hardness, reduce scratches, scratches and chemical treatment; ?? D. Two kinds of surface treatments can be performed (that is, glossy and matte). The differences are as follows: ?? The two transparent metal layers of the four-wire resistive touch screen each increase 5V constant voltage when working: one vertical direction and one horizontal direction. A total of four leads are required for the entire touch screen. Its service life is no less than 1 million times for a single touch, and no less than 100,000 times for a line. IQTouch K interactive touch screen feature 20-point touch and dual system -- Android 8.0 system and optional OPS Windows 10Pro system. Its 4K UHD resolution facilitates presentations and collaboration. With optional multi-screen casting software, IQClass 6.0 and installation-free IQClass Plus software, IQTouch K Series can help create an interactive and collaborative teaching atmosphere in class.

Let’s See IQTouch K Interactive Display

4K UHD Display

Stunning 4K UHD can display a cystal clear image on

screen.

20 Touch Points

Enable an interactive and collaborative teaching atmosphere

in classroom.

Built in Wifi hotspot & Optional

Multi-screen casting Software

Support to cast your devices to the screen wirelessly,

and your devices can control the screen wirelessly.

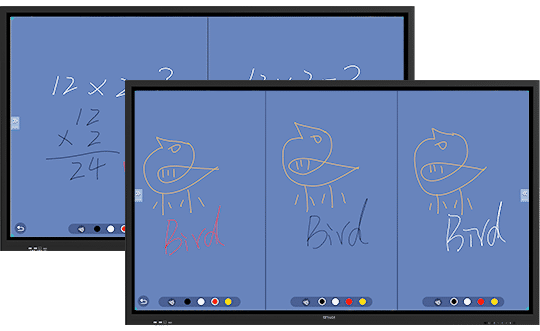

Easy-to-Use Built-in Whiteboard

Software

Built-in Whiteboard software under Android system allow to do

two separate screen teaching and three separate screen teaching.

All-channel Annotation

Enable to annotate under Android system and

Windows system.

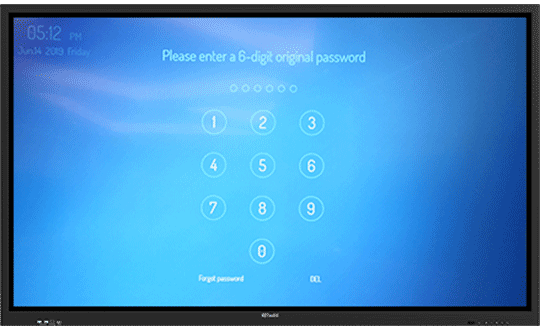

Power On/Off Lock and Screen Lock can

be Set with A Password Respectively

Support to lock screen and lock power on/off button

to avoid student

malfunction and secure privacy.

To compare with our other IQTouch Series

RESOURCE FOR YOU

RESOURCE FOR YOU

Copyright © 2017.Returnstar Interactive Technology Group Co., Ltd All rights reserved.